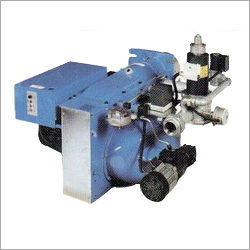

Steam Boiler

Product Details:

- Size 25*12*10 Inch

- Color Blue And Grey

- Usage Industrial

- Product Type Boiler

- Condition New

- Type Once Through

- Structure Fire Tube

- Click to View more

Steam Boiler Price And Quantity

- 1 Unit

Steam Boiler Product Specifications

- 25*12*10 Inch

- Cast Iron

- Boiler

- Once Through

- High Pressure

- Blue And Grey

- New

- Fire Tube

- Industrial

Steam Boiler Trade Information

- 50 Unit Per Day

- 1 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

An example of a steam boiler is a boiler that produces steam by heating water with an external heat source. It is frequently employed in heating systems, power generating, and industrial applications. Steam boilers are useful for a variety of processes and applications because they can produce steam at high pressures and temperatures.

Here is a list of a steam boiler's essential parts and how they operate:

1. Burner powered by biomass, natural gas, oil, or coal can be used as a steam boiler's heat source. An electric heating element is another option. The water's temperature is raised by the heat produced by the heat source.

2. Water Vessel: A steam boiler's water vessel is often a sizable metal container used to hold water. In order to accommodate the steam generating process, the vessel is made to endure high pressures. To ensure optimal operation and safety, the water level is meticulously maintained.

3. Combustion Chamber: To produce heat, fuel is burned in the combustion chamber of steam boilers. Through heat exchanger surfaces or tubes, the heat produced by combustion is transmitted to the nearby water. Depending on the boiler design, the combustion chamber may be placed either within or outside the water vessel.

4. Water Tubes: Steam boilers cannot function without water tubes. They transport water and are found inside the heat exchanger or combustion chamber. These tubes are surrounded by hot combustion gases that heat the water inside by convection. Water turns into steam as it absorbs heat.

5. One essential part of a steam boiler is the steam drum. Steam and water are separated in a sizable chamber that is situated above the water vessel. Any residual water droplets are separated and returned to the water vessel when the steam rises to the top of the steam drum. Additionally, the steam drum contributes to assuring the calibre of the steam produced.

6. Steam boilers are fitted with a number of safety mechanisms to ensure their operation is secure. A few of these are pressure relief valves, which let out extra pressure to stop explosions. The operation of the boiler is also monitored and controlled by other devices and controls, such as temperature sensors, pressure switches, and water level controls.

7. Steam is generated and then sent through pipes to be used in turbines, heat exchangers, and heating systems, among other devices. The energy from the steam is used to run equipment, generate heat, or carry out numerous industrial procedures.

Steam boilers require routine maintenance, which includes water treatment to stop corrosion and scale. To maintain correct and effective operation, they also require routine cleaning, inspections, and safety checks.

In order to ensure safety and optimal performance, steam boilers should only be installed, operated, and maintained by skilled personnel because they operate at high pressures and temperatures.