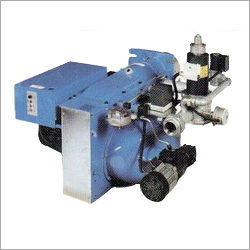

Light Oil Burners

Product Details:

- Color Black and Grey

- Product Type Burners

- Size 10*12*6 Inch

- Usage Hotel, Restaurant, Commer

- Condition New

- Type Once Through

- Structure Fire Tube

- Click to View more

Light Oil Burners Price And Quantity

- 1 Piece

Light Oil Burners Product Specifications

- High Pressure Pa

- New

- Once Through

- 10*12*6 Inch

- Hotel, Restaurant, Commer

- Cast Iron

- Fire Tube

- Burners

- Black and Grey

Light Oil Burners Trade Information

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- 50 Piece Per Day

- 1 Days

- Australia, Africa, Western Europe, Middle East, South America, Asia, Central America, Eastern Europe, North America

- All India

Product Description

Burners known as "light oil burners" are used to ignite light liquid fuels, such as light oil or diesel oil, in a variety of heating appliances like boilers, furnaces, and ovens. These burners are made to atomize and burn the liquid fuel to produce heat effectively.

Here is a description of how light oil burners work in general:

1. Fuel Delivery: Light oil is delivered to burners via a fuel supply system that is connected to the burners. Fuel can be kept in tanks and delivered to the hob with the use of pumps and pipelines.

2. Fuel Atomization: To enable effective combustion, light oil burners feature an atomizing mechanism, typically a nozzle or sprayer, that disperses the liquid fuel into tiny droplets. The fuel's surface area is increased during the atomization process, which improves mixing with the combustion air.

3. Air Supply: Proper fuel and air mixtures are necessary for combustion. Light oil burners have an air supply system that provides the burner with the necessary quantity of combustion air. Usually, preheating the air improves combustion performance.

4. The combustion chamber or combustion head of the burner is where the light oil and air are combined during the combustion process. Depending on the burner design, either a continuous pilot flame or an electric spark ignites the atomized fuel. The heat needed for the intended application is produced by the flame that results.

5. Burner Control: To ensure optimal combustion, light oil burners are fitted with control systems that manage the fuel and air flow. These controls provide an appropriate air-to-fuel ratio, stable flame, and effective operation. Depending on the amount of heating required, the control systems may have mechanisms for regulating the fuel and air flow rates.

6. Light oil burners are equipped with a number of safety mechanisms to guarantee their operation is secure. These could include high-temperature limit switches to stop overheating and flame monitoring sensors to detect flame failure and automatically cut off the fuel supply.

High combustion efficiency, dependable operation, and fuel availability flexibility are all benefits of using a light oil burner. Due to its relatively high energy density and simplicity of storage, light oil is a fuel that is frequently employed in a variety of applications.

It's crucial to remember that light oil burner installation, operation, and maintenance should be handled by competent personnel who follow the manufacturer's instructions. To guarantee optimum efficiency and safe operation, the burner components need to be regularly inspected, cleaned, and adjusted.